S/W Quality Assurance Plan, meeting the following objectives: QC staff documents the results of product testing based on the standardized procedures for product validation.With reference to Table 9.20, the following deliverables are required as evidence of S/W development process assurance: Quality Control is the responsibility of a particular personnel within the quality management team whose duties include following the standard operating procedures for product testing. Each team member is responsible for the standard operating procedures and contributes towards designing the quality measures. Quality Assurance activities involve the entire quality management team. QC confirms the safety of the products.ĥ.

Quality assurance activities and processes verification#

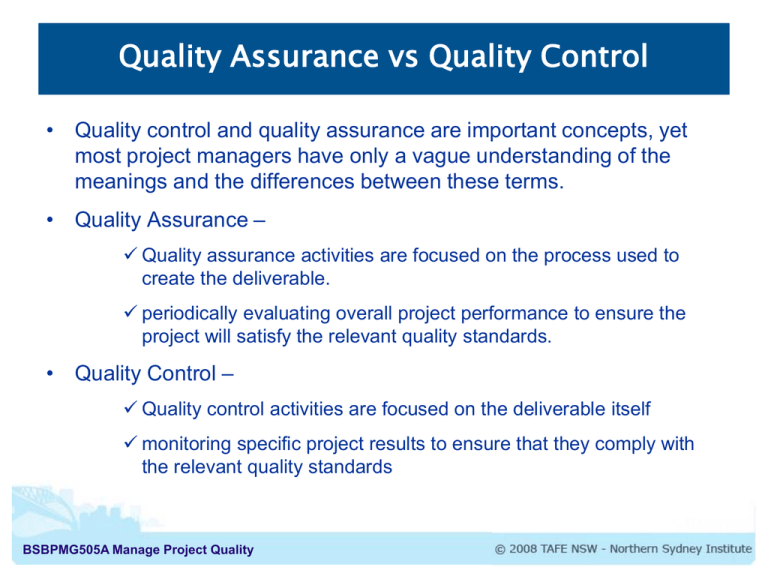

They include verification of various parts of the product post-production and before distribution. QC activities are the verification or testing criteria for manufactured products. These standards act like guidelines during the entire process of product development and ensure the output meets the desired standard of quality. They include defining quality standards for product design, manufacturing, packaging, distribution, marketing and sales. QA activities act like a roadmap for creating high quality products and services. Used Mainly During Creation Process or Testing Process QC efforts are more inclined towards testing parts of the product once they are ready.Ĥ. The QA system dictates various processes to ensure inputs are consistently safe and effective, such as auditing suppliers and raw materials. Quality Control measures parts of the system including the outputs.

Quality Assurance controls the entire system of product development including various processes and procedures designed to ensure quality standards. Controls the Entire System or Controls Each Process QA involves the processes that create the product, while QC is focused on the product output.ģ. It identifies the quality issues in the products that are already manufactured. The processes are designed to avoid any defects in the deliverables. It solely focuses on preventing quality issues. It also ensures they meet the desired standards of quality and efficacy. QC focuses on testing the products once they are manufactured to ensure all the safety measures are met. It makes sure procedures and processes are followed to deliver a safe, effective product of desired quality.

QA focuses on steps to design processes, such as documenting standard operating procedures (SOPs). It works towards preventing defects before they occur through process design while Quality Control is reactive and it identifies defects after their occurrence. Here are 5 major differences between Quality Assurance and Quality Control to help you understand the concepts better. QC is a set of actions that test the procedures used to verify that a product is safe and effective after manufacturing. QA is a set of actions taken to design and manufacture a safe and effective product by building quality controls into the product life cycle. It is crucial for the success of the project to understand the difference between Quality Assurance and Quality Control.

0 kommentar(er)

0 kommentar(er)